电脑三层,五层瓦楞纸板生产线

发布时间:2017-05-24 15:50:41

用途与特点

♦材料选用好错钼合金钢。

♦瓦楞形状为国际通用UV形,经精心设计,缩纸率低,压制出的纸板质 屋好,强度高。

♦采用进口精密机床,先进的成型磨削和电脑分度工芝,保证楞型尺寸 精度符合**标准。

♦楞齿表面经中频淬火处理,硬度达到HV60O以上。上瓦楞辊有中高, 呈腰鼓形,使用寿命长。

Function and features

The corrugating roll is made of chrome molybdenum alloy steel

UVtype is selected for corrugated rollers,which are elaborately designed with lower take up ratio and high cardboard intensity.

Corrugated roller ground with advanced molding and computer indexing technology and guarantee the size of corrugation conform to national standard.

Surface manufacture with intermediate frequency quenching heat treatment,hardness have reached up to HVR60O .which is characterized by perfect flute and long service life.

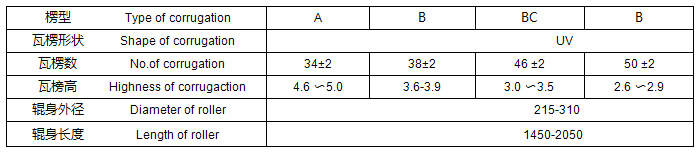

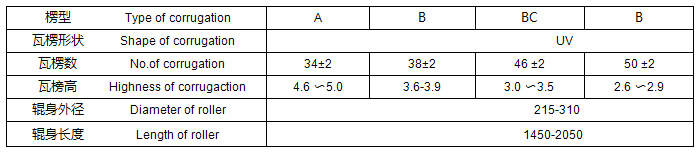

主要技术参数 Main technologica丨 parameter

主要技术参数 Main technologica丨 parameter

用途与特点

此流水线适合大批量自动化生产,能制造出符合**标准的优良瓦楞纸板,生产效率高,纸板质星好,妥取集中控制,操作筒便,维修 方便,安全可靠,大大降低了工人劳动强度。该生产线采用目前国际**新节能方式,用高温导热油给整机提供热源,较蒸气加热节约能源 60°/。以上,大大降低了能耗,有效的压缩了生产成本,是当今经济型的理想产品,适合大中型纸箱厂使用。

―、整机总长度60米。

二、 整机总动力110kw。

三、 无轴支架:双臂独立升降。

四、 瓦裱机:瓦楞辊直径265mm-310mm,电机功率11kw-17kw,采用电磁调整电机。

五、 双筒粘腔机:果用上、中两层涂胶下端面纸导纸辊。

六、 烘千机:总长度10米,由14块加热板组成。气动涨紧装置,传送带停电自动分离。

七、 定型部分:总长6米,由27对成型轴组成。

八、 纵切机:根据用户要求可选装超薄刀和普刀两神,自动化程度高,操作筒便。

九、 横切机:分为电脑单双刀和机械单双刀共四神选配方式,供客户选择。

十、锅炉、燃媒能耗120公斤/小时。

锅炉属无压节能型,本机升温从0°C至开机温度不超过两小时油料基本没有消耗。

Function and features:

This production line is suitable for large quanity automatized manufactuing and it can produce good quality corrugated cardboard which can meet national standard completely. Higher productivity, better paper board quality, adoption of central control system, simple and easy operation, convenient to repair and maintenance, reliable and safe, greatly lower degree of manpower requirement .This production line adopts the most updated source-saving mode which get heat from the high-tempeture guiding oil.Compared with the steam heating ,it reduce the source by 60% so that cut the cost effectively.lt is economical ideal product and suitable for big and medium carton maunfacture.

1 .The whole length of the machine is 60 meters.

2. The whole power of the machine is 110kw.

3. Mill roll stand:the two holder can lift and lower independently.

4.Single facer:The diameter of the corrugating roll is 265mrr>310mm.the power is 11 kw*17kw

5. Double layer guling machine:Using the top and middle layer for gluing and the bottom for vonveying the reel paper.

6. Drying machine:the total length of the machine is 10 meters and it is made of 14 pieces of heater pi ate.Pneumatic strain device and conveyor belt separate automaticaly once the power cut.

7. Definite form part:the whole length is 6 meters and it is consist of molded axle.

8.Slitting machine:there are thick knife and common knife for chosening.High degree automation and easy operation.

9. Transverse cutting machine:There are four matching mode which are computerized and mechnical single-double knife for client to choose.

10. The coal consumption for the boiler is 120 kgs/hour.

The boiler belong to the energy-saving type without pressure.lt won consume the oil within two hours from Ot to starting the machine.